- Test and Measuring Instruments

- DataTaker

- B&K Precision

- BrianChild

- Chauvin Arnoux

- Machine and Equipment Testers

- Accessories

- Adapters For Multimeters and Multimeter Clamps

- Calibrators

- Current Clamps and Sensors

- Earth and Resistivity Testers

- Electrical Installation Testers

- Electrical Testers

- Electromagnetic Field Testers

- Insulation testers

- Locators - Detectors

- Loggers

- Micro-ohmmeters

- Multimeter Clamps

- Multimeters

- Physical and Environmental Measurements

- Power, Energy and Disturbance Analysers

- View All

- CR Magnetics

- Elcontrol Energy Net

- Extech

- Accessories

- Air Flow Meters

- Air Quality Meters

- Automotive Meters & Testers

- Battery Testers

- Borescopes & Video Inspection Cameras

- Cable Tracers

- Calibrators

- Circuit Identifiers

- Clamp Meters

- Continuity Testers

- Decade Boxes

- Distance Meters

- Electromagnetic Field Meters

- Force Gauges

- Gas Detectors and Analyzers

- Ground Resistance Testers

- Humidity Meters | Hygrometers

- LCR Meters

- Light Meters

- Magnetic Field Meters

- Megohmeters / Insulation Testers

- Milliohm | Micro-Ohm Meters

- Moisture Meters

- Multimeters

- Oscilloscopes

- Pedometers

- Phase Rotation | Motor Rotation Indicators

- PID Controllers

- Power Analyzers

- Power Supplies

- Pressure Meters - Manometers

- Receptacle Testers and AC Circuit Analyzers

- Refractometers

- Scales

- Sound Meters | Decibel Meters

- Stopwatches, Timers and Clocks

- Tachometers

- Thermometers

- Thickness Gauges

- Vibration Meters

- Voltage and Current Testers

- Water Quality Meters

- View All

- HT Instruments

- Voltage detectors and others

- Borescopes

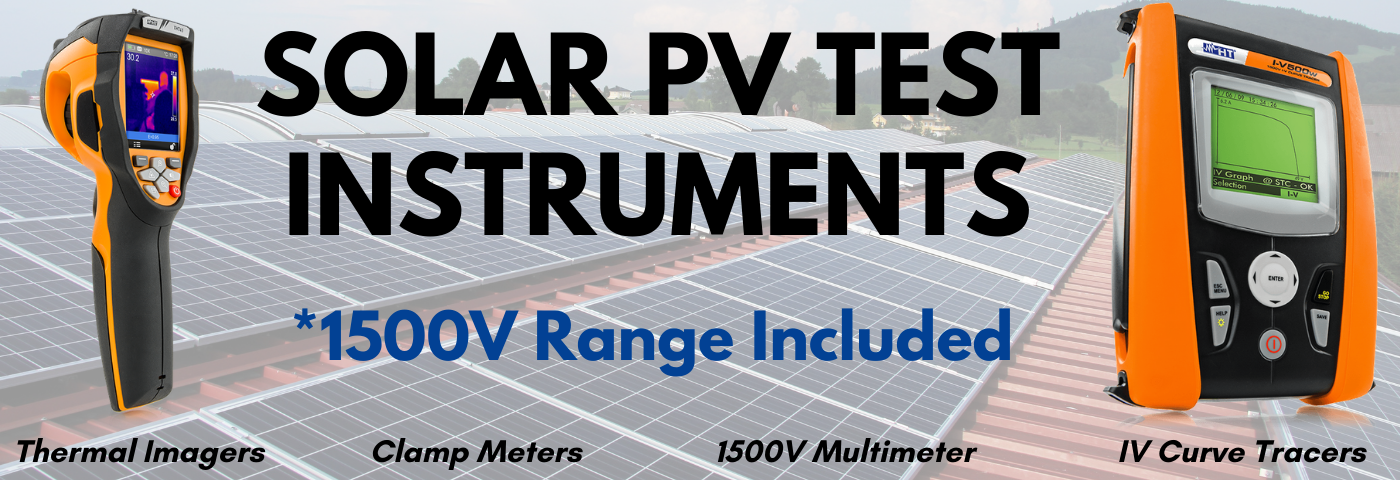

- Clamp Meters

- Digital Multimeters

- Environmental measurements

- Gef Tools - 1000V Insulated Cutting Tools

- Gef Tools - 1000V Insulated pliers

- Gef Tools - 1000V Insulated screwdrivers

- Gef Tools - Cable peelers

- Gef Tools - Crimpers

- Gef Tools - Pouch For Screwdrivers With Interchangeable Blades

- Gef Tools - Various tools

- Infrared Cameras

- Installation Testers

- LAN Networks

- Laser distance meters

- Led Lamps

- Mobile APP

- New products

- Photovoltaic Testers

- Power Quality Analyzers

- Process calibrators

- Scissors

- View All

- Lambrecht

- Metrix

- Miltronics

- Multimetrix

- Sefram

- Super Systems

- Texas Electronics

- Ventilation Control Products

- Work Italia

- Clamps and accessories for Short Circuiting and Grounding Equipment

- High Voltage Short Circuiting and Grounding Equipment

- Insulating rods

- Low Voltage Short Circuiting and Grounding Equipment

- Medium Voltage Short Circuiting and Grounding Equipment

- Railway and underground lines equipment

- Safety Kits, Insulting Materials and Products

- Voltage detectors

- View All

- View All

- Stock Clearance Items

- Industrial Automation Technology

Atmosphere Furnace Systems

| Previous | 8 / 9 | Next |

Atmosphere Furnace Systems Video

Super Systems provides furnace control panels for new and existing furnace applications. Our control systems are designed based on furnace specifications and customer requirements. We have addressed almost every atmosphere application in heat treating with various control packages. The controls are designed to meet industry specifications such as AMS 2750, 2759 and NFPA. We build control panels that are efficient for operators to use, conserve floor space and include all drawing sets and installation services.

Features

Bell Annealing

Features

PC Solutions

Features

Retrofit Plates

Features

3 Door Hoffman

Features

Four (4) batch furnaces (SSi's 9000 Series Controllers & 7EKs)

Four (4) temper furnaces & four (4) washers

15'' color operator interface (touch-screen)

Allen-Bradley MicroLogix 1200 PLC

PC Configurator™

Bell Annealing

Features

SSi's 9000 Series with Touch Screen HMI

Allen-Bradley PLC

PC Configurator

Large color operator interface (touch screen)

PC Solutions

Features

Quench temperature control and hi-limit

Dell computer (inner door-mounted)

SSi's SuperDATA™

PC Configurator™

Large color operator interface (touch screen)

DPC2530 - Continuous Dew Point Analyzer

Keyboard and mouse shelf

Retrofit Plates

Features

SSi's 9000 Series dual-loop controller (Ethernet and RS485 Modbus RTU communication ports)

Recipe control for easy-to-program and easy-to-run cycles

Atmosphere and Temperature Control

User-defined events and alarms

PLC for furnace mechanical movements and safety circuits

Furnace hi-limit controller (7SL)